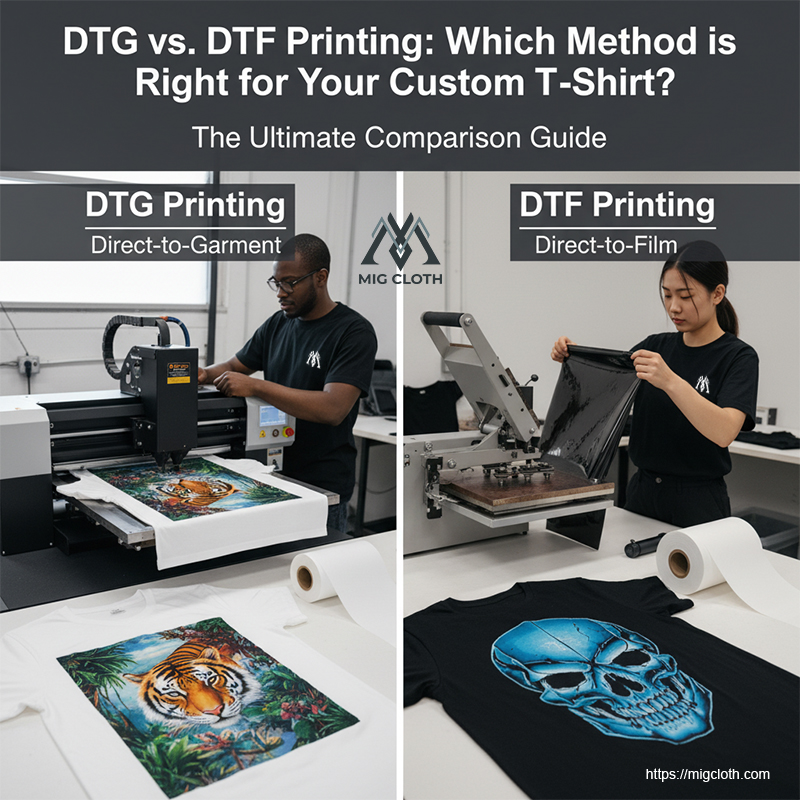

At Migcloth, we specialize in both DTG (Direct-to-Garment) and DTF (Direct-to-Film) printing - two of the most advanced methods in the custom apparel industry. While we use both techniques daily, understanding their differences will help you choose the perfect option for your project.

DTG Printing: The Digital Artisan

How It Works:

DTG printing works like a sophisticated inkjet printer directly onto garments. It uses specialized water-based inks that bond with cotton fibers at a molecular level.

Best For:

- 100% cotton fabrics - excels on natural fibers

- Complex, full-color designs - photographs, gradients, detailed artwork

- Small to medium batches - no setup costs make it economical for limited runs

- Soft-hand feel - the print becomes part of the fabric

Advantages:

- Photorealistic quality - exceptional detail reproduction

- No minimum quantity - perfect for single pieces or small orders

- Eco-friendly inks - water-based and softer on the environment

- Quick turnaround - no lengthy setup process

Limitations:

- Works best on cotton - less effective on polyester blends

- Requires pretreatment - needs special coating for dark garments

- Slightly higher cost per unit for larger quantities

DTF Printing: The Versatile Performer

How It Works:

DTF prints your design onto a special film, then uses adhesive powder and heat to transfer it onto the garment. The result is a durable, flexible transfer.

Best For:

- All fabric types - works equally well on cotton, polyester, and blends

- Bold, vibrant designs - excellent color opacity and saturation

- Mixed material garments - perfect for shirts with cotton/polyester tags

- Production runs - efficient for medium to larger quantities

Advantages:

- Fabric versatility - consistent results on any material

- Excellent durability - withstands repeated washing

- No pretreatment needed - faster production on dark garments

- Great color vibrancy - particularly on dark fabrics

Limitations:

- Slight texture - you can feel the print on the fabric

- Film and powder costs - can be less economical for single items

- More complex process - requires additional equipment

Understanding the Differences: DTG vs. DTF

Let's break down the key differences between these two printing methods in an easy-to-understand format:

For Optimal Fabrics:

- DTG excels on 100% cotton fabrics that absorb ink perfectly

- DTF works exceptionally well on all fabric types, including cotton, polyester, and various blends

Design Complexity:

- DTG delivers the best results for detailed designs like photographs, subtle color gradients, and intricate artwork

- DTF is ideal for bold designs with solid colors and clear boundaries

Final Result and Texture:

- DTG produces a soft, integrated feel with the fabric, as if the design becomes part of the material

- DTF creates a slightly textured result that remains highly flexible and durable

Performance on Dark Garments:

- DTG requires special pretreatment to ensure ink adheres optimally to dark garments

- DTF delivers excellent results directly on dark-colored fabrics without complex processes

Cost Efficiency:

- DTG is most efficient for small orders (1-20 pieces) due to no setup costs

- DTF is more economical for medium orders (20+ pieces) with consistent quality

Durability Level:

- DTG offers very good durability with proper care

- DTF is known for excellent durability that withstands repeated washing

Production Speed:

- DTG is very fast for small orders with a simple process

- DTF is more efficient for batch production in medium to large quantities

How We Choose at Migcloth

While we master both techniques, here's our internal decision process:

We typically recommend DTG when:

- Your design has photographic elements or subtle gradients

- You're ordering 1-20 pieces of 100% cotton garments

- The highest softness and integrated feel are priorities

- You need quick turnaround on sample pieces

We typically recommend DTF when:

- Your garments contain polyester or mixed fabrics

- You need vibrant results on dark-colored shirts

- You're ordering 20+ pieces of the same design

- Maximum durability and wash resistance are crucial

Real-World Examples from Our Shop

Case Study 1: Band Merchandise

- A local band needed 50 shirts with a detailed graphic novel-style design

- Our choice: DTG printing

- Result: Photographic quality preserved, soft feel appreciated by fans

Case Study 2: Corporate Event

- A company ordered 100 polo shirts (cotton-polyester blend) with logos

- Our choice: DTF printing

- Result: Consistent, durable prints that maintained professional appearance through repeated wear

Your Project, Your Choice

Still unsure which method is right for your custom t-shirts? Consider these questions:

- What's your garment material? (Cotton = either, Polyester = DTF)

- How complex is your design? (Detailed artwork = DTG, Bold graphics = DTF)

- What's your quantity? (1-20 = DTG, 20+ = DTF)

- How important is fabric feel? (Ultra-soft = DTG, Durable = DTF)

Need Professional Advice?

Our printing experts can analyze your design and recommend the perfect method for your project.

[Contact Our Printing Specialists]